Rail 101 Part Two: Switching and Blocking Cars for Outbound Movement on Manifest Trains

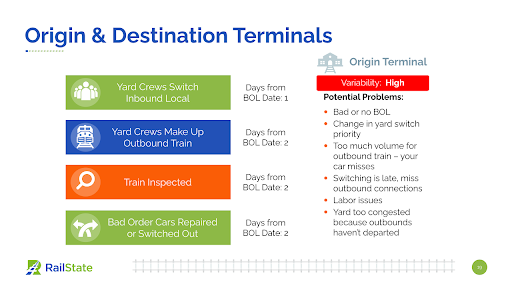

In part one of our Rail 101 series, I discuss origin and destination terminals, and how they’re a major source driving problems and delays in rail shipments. Part Two of this course describes the process of switching and blocking cars for outbound movement on manifest trains.

Railroads behave similarly to airports in that not all yards make trains destined to every other yard. Consider flights you’ve taken; if you’re flying from Fort Wayne, for example, and your ultimate destination is Denver, you won’t find a direct flight between the two cities. You’ll need to stop at a larger airport, with more connection options. The same goes for trains. Cars that are ultimately headed to different destinations might be on the same train, or block. A “block” is a group of cars going to a particular destination. Switch crews will switch cars arriving on an inbound train to the proper outbound train. The yardmaster provides a switch list to the crew. A “switchlist” is a set of instructions showing on which tracks to put each car from that inbound train, to make the next outbound train connection. See below:

In the above table, you’ll see a variety of cars heading to multiple destinations. All of the above cars are at Hinkle Yard, and are on one track. The switch list shows the list of cars, load/empty status, waybill destination, the block in which cars for those destinations are to move from Hinkle, and the track the yardmaster has designated for that block. In this case, you can see cars moving to Stockton, CA, Coos Bay, OR, and Laredo, TX will all go in the Roseville block, despite their differing ultimate destinations. They will connect in Roseville for their ultimate destinations. The switch crew will move each car from the current track to those tracks designated on the switch list.

They continue with this process, switching each inbound train, until they’ve completed all of the inbounds, and the yard master cuts them off. At this point, it’s time to make up the outbound trains.

A different yard crew is generally responsible for making the outbound trains. That crew will make sure all the cars are coupled, and will couple the air hoses (unless there are mechanical forces available to perform that task). Once all cars are coupled, and air hoses coupled, the train is inspected. Bad order cars will be moved, and cars in-need of repairs will either be repaired on-the-spot, or moved to a repair track.

Again, this portion of operations has a high degree of variability:

The above list encompasses several of the problems that could occur in the process of making outbound trains. The reality is that these delays happen every day. Trains that were supposed to be switched first could be moved to third or fourth; outbounds can depart late; crews can be overloaded with volume; or there could be a bad (or non-existent BOL). With so many moving parts, it’s no wonder these terminals cause delays.

Once a train is finally ready to depart, a road crew is assigned to take that train from its current yard, to whichever is the next on its journey. The crew or mechanical forces perform an air brake test. The conductor walks both sides of the train to make sure the brakes are applied. The engineer then releases the brakes, at which point, the conductor does another walk-around. The speed with which a train charges depends on the weather. Moisture in the air brake system can freeze and make it difficult to charge the air brake system to 95 pounds at the rear of the train. Railroads will compensate by making trains shorter in the winter.

To summarize: manifest shipments experience switching and other work events en route. They are generally handled multiple times en route, and move on multiple trains. The variability of this process is high, due to the amount of coordination necessary, and the possible missteps.