Top Takeaways from Railroad 101: Understanding Origin and Destination Terminals

Our co-founder, John Schmitter, has worked in the rail industry for over 40 years. As such, he has a deep understanding of how the industry works, and is well-aware of its strengths and weaknesses. His presentation, “Railroad 101: Introduction to Railroad Operations” paints a picture of general rail operations. We’re breaking it down into digestible bits.

When understanding Rail 101, it’s important to realize the sources of delayed cars and other problems. Origin and destination terminals (first and last mile) involve many “work events,” and are the major sources driving problems with rail shipments.

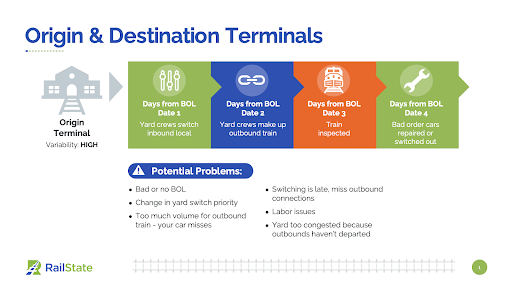

What happens at these terminals? Local crews pick up and deliver cars to industries and interchanges on branch lines, or on segments of more congested lines. They pull the car from your plant and other plants, and return to the serving yard with those cars for processing. But there are many things that can go wrong. Some examples of events that can go wrong at origin terminals include: the local crew not making it to the plant because of too much volume to deliver or pick up; not enough time before their hours of service expire; derailment; network congestion; bad order cars; changes in priority; or insufficient crew availability to fill all the jobs. See the below graphic:

If any one of the above events goes wrong, shippers lose time and money. Usually, if a switch is missed, the cars will be picked up on the next service, which results in at least a day’s delay.

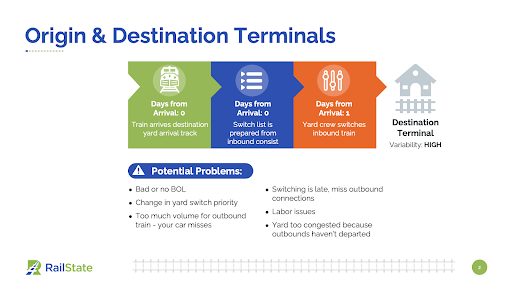

What about once the train makes it to the yard? Once the train is in the yard, a yard crew switches the cars from incoming trains to outgoing ones. The train must be inspected, and an air brake test conducted, before the train departs. With permission from the dispatcher, the train departs for the next terminal. See below:

So what’s our takeaway from this first intro to Rail 101? Origin and destination terminals are the greatest source of delays, inconsistencies, and problems with rail shipments.

With so many areas for possible delays, you’d think being able to see a real-time picture of the network as a whole would be paramount — and yet, before RailState, a real-time source for network visibility didn’t exist. Railways are in the business of moving freight; our business is reporting on what is happening on the rail network. Our network of sensors creates a huge traffic database, which allows you to see — in near real-time — when and where slow-downs occur; which routes and ports/terminals are preferable to others; and which trains are being prioritized. If you’re shipping, RailState gives you the power to better plan your shipments and avoid congestion. As a result, you save time and money, and perform better.